Dräger X-dock 5300/6300/6600 Calibration and Bump Testing

$3,915.00 – $5,959.00

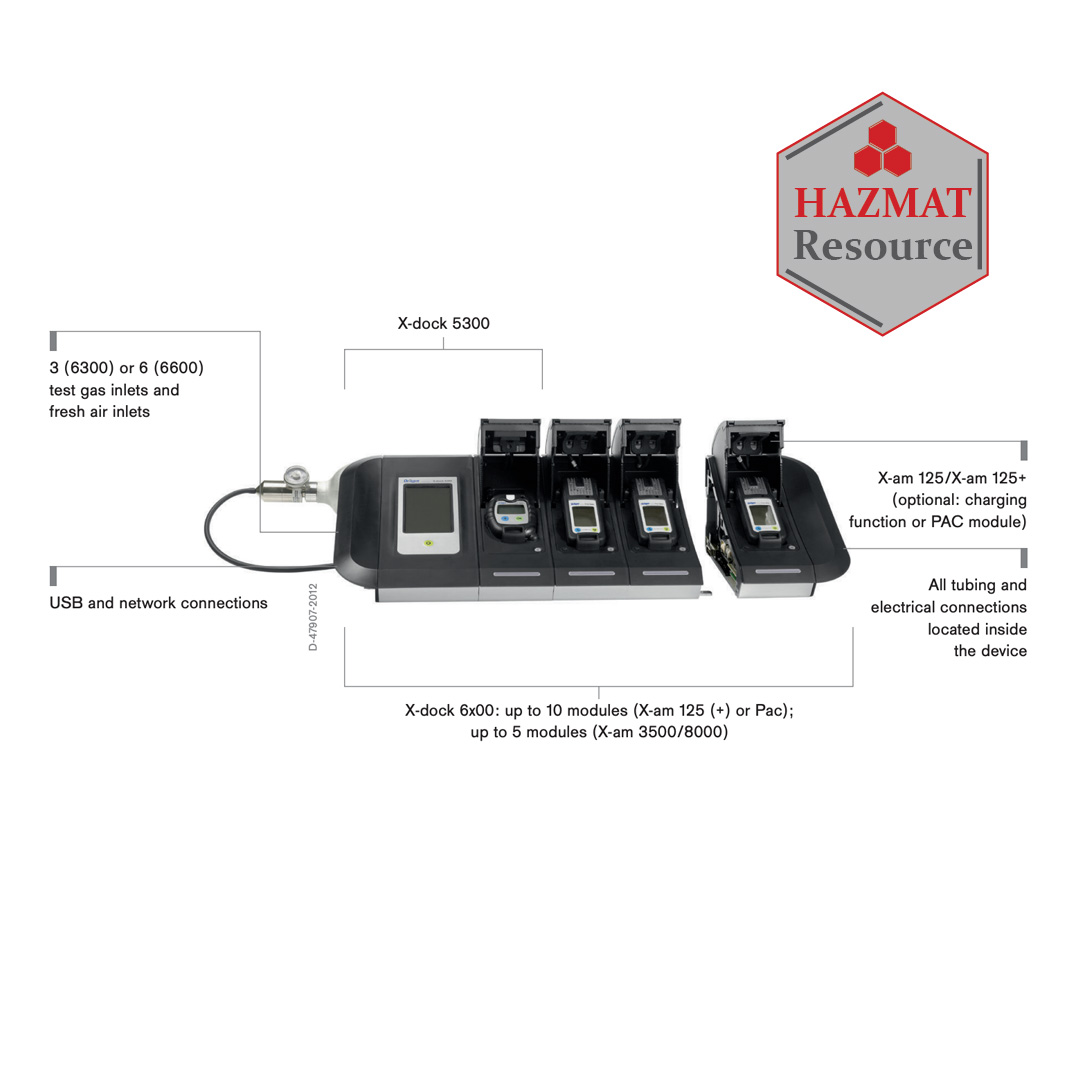

The Dräger X-dock 5300/6300/6600 Calibration and Bump Testing allows for automatic bump tests, calibration, reduced test gas consumption, short testing times, and comprehensive documentation come standard in this new device from Dräger, the experts in gas detection.

As the X-dock system is very customizable with up to 10 separate modules. For assistance please ‘Request a Quote’ or call +1 805-617-0987 email sales@hazmatresource.com with any questions.

Description

Dräger X-dock 5300/6300/6600

Work smarter, work safer

The X-dock engineered advantage all starts with intuitive touchscreen operation at the master controller station where up to three test routines can be configured. Testing is as simple as inserting your Dräger gas detection instrument and closing the lid. The Draeger x dock immediately detects all sensor combinations and automatically tests and adjusts when all of the required test gases are connected. All generated data is documented in the database.

Comprehensive documentation

All of the relevant data from the test is collected for detailed evaluations providing you with the tools for unparalleled analytics. The Dräger x dock calibration procedure include the report wizard which can be used to create customized reports and calibration certificates can be printed right at the stations via PostScript-compatible USB printers. Also documented are items such as instrument operational status and name of tester.

Convenience and control

The X-dock Manager software produces a detailed evaluation of the data in the calibration system and gas detection instruments and presents the information in various graphics and statistical models—providing you with a comprehensive overview of all results. Multiple X-dock systems can be connected in a network giving all users access to data in a central database.

Configurations for every need

The Dräger X-dock on all sitings comes in multiple configurations to allow for flexibility, depending on the type of detection instrumentation being used.

The X-dock 5300 includes a master controller with a module for a single gas detection instrument in the X-am 1/2/5000 or Pac^1 family of products. The X-dock 6300 and 6600 versions can be configured freely. They consist of a master controller and can be expanded with up to 10 modules for X-am 1/2/5000 and/or Pac single gas detection instruments.

Reduced test gas use means reduced costs

With a reduced gas flow (300 mL/min instead of 500 mL/min = 40% decrease) per module, you save money on test gases. Short testing times also reduce the overall maintenance requirements. Dräger‘s patent pending innovative valve concept only needs one pump, which means less wear on parts for you. The valves automatically switch the test gases and the fresh air source as well.

Time is money. You save both with the X-dock

Up to 10 modules can be connected to the X-dock, allowing you to test gas detection instruments simultaneously or independently of each other. The automatic Draeger X dock bump test station also saves time, because the test only takes 8 to 15 seconds. All Dräger test gas cylinders are already stored in the database—just enter the part number to automatically fill the fields required for the gas configuration, eliminating the need for manual data entry.

Additional Benefits

- Touchscreen operation at the master controller station

- Up to three configurable test routines

- Automatic permeability tests

- Automatic tests of all alarm elements (acoustic, visual and vibration alarms)

- Optional charging function for X-am 1/2/5×00

- Easy to replace seal cartridge

- 12V operation (e.g., in vehicles)

- Can be subsequently expanded with up to max. 10 modules (X-dock 6300/6600)

- Sensor performance testing

Contact us for a quote on all your Draeger X dock calibration procedure needs and ask for our best Draeger X Dock price.

| Dräger X-dock user manual pdf | Dräger X-dock Technical Manual | Dräger Calibration Gas & Accessories |

About Draeger

Dräger manufactures medical and safety technology products. In so doing, Draeger protects, supports, and saves people’s lives around the world with fire departments, hazmat, and emergency services. Founded in Lübeck in 1889, Dräger has grown into a worldwide, listed enterprise. It is in its fifth generation as a family-run business. Dräger has more than 15,000 employees worldwide and is present in over 190 countries around the globe. In 2020, the company generated net sales of around EUR 3.4 billion.Hazmat responders all over the world use Dräger technology. It operates in around 50 countries with its own sales and service companies directly on location where its customers are. Dräger X-dock 6300 – HazMat teams rely on HAZMAT Resource, get on-board and request a quote today!

Dräger VOICE – your hazmat-based safety product finder

Dräger HazMat VOICE is an essential tool for the safe handling of hazardous materials. One click and you’ll receive relevant information and specific recommendations of safety equipment for more than 1,500 hazardous substances in its database. Give it a try – it is so simple https://www.draeger.com/en-us_us/Substances

Need More Information?

For more information about the available Dräger x dock bump test station accessories, gas detection devices, and Dräger X-dock 6600 calibration needs contact us today!

Dräger Up with the X-am Dock

For the following manuals see the pdf links above or contact us for specific information.

- Draeger X-dock 5300 manual

- Draeger X-dock 6300 manual

- Draeger X-dock 6600 manual

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| X-dock | X-dock 5300 PAC Series, X-dock 5300 X-am 1/2/5×00, X-dock 5300 X-am 3500/8000, X-dock 6300 X-am 1/2/5×00, X-dock 6300 X-am 3500/8000, X-dock 6600 X-am 1/2/5×00, X-dock 6600 X-am 3500/8000 |